Welcome to the website of Shanghai Endek Machinery Co., Ltd

hotline:+86-021-52822070

NEWS

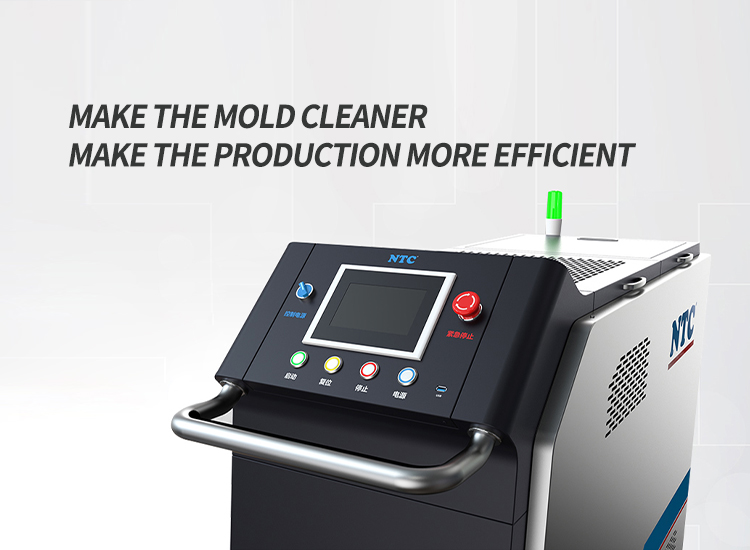

NEWSIn modern factories, the business strategy of saving manpower, improving quality, and reducing costs in response to market competition is urgent. The use of water-based mold heaters can reduce mold preheating time, improve the surface quality of finished products, and fully automate production, which is a necessary means to improve mold life and productivity.

Water mold temperature machines can reduce the production of low-quality products and improve product quality through temperature control. In the plastic industry, temperature control plays an important role in the product shaping process. Good temperature control and temperature control can help us better grasp the production and shaping of products, and avoid the production of low-quality products.

The water mold temperature machine is mainly used for heating and constant temperature of molds, using ordinary tap water as the heat transfer medium. It can maintain the mold temperature to 180 ℃ high temperature to meet the requirements of heating and constant temperature. It relies on the principle of increasing the boiling point of water under a unique high-pressure environment, and adopts microcomputer temperature control to ensure high-performance stable temperature control, with a control accuracy of ± 1 ℃.

Features:

1. Silent, energy-saving, low energy consumption, and high temperature control accuracy.

2. Made of imported heating wire and seamless stainless steel pipe, with short heating time.

3. All stainless steel material, corrosion-resistant, durable, safe and reliable.

3. Performance is safe, reliable, and highly automated. Compact structure, beautiful and generous appearance, easy to use, good energy-saving efficiency, energy-saving and durable, and long service life.

4. Small in size and occupying less land, it can be installed near thermal equipment without the need for a dedicated boiler room or dedicated personnel to operate. It can reduce equipment investment and operating costs, and recover investment quickly.

5. Heating is uniform and flexible, and temperature adjustment adopts PID self-tuning intelligent control, with high temperature control accuracy of ≤ ± 1 ℃, which can meet the strict requirements of high process standards.

Steps for using a mold temperature machine:

1. Check and set up before machine testing. Check if the oil, electricity, gas, and pipelines of the mold temperature machine are normal. Open the control panel, enter the operation interface, and set the temperature. However, it should be noted that the set temperature should be lower than the oil outlet temperature;

2. Run the inspection, start the oil pump, check if the steering of the oil pump and fan is correct, and confirm that the fan and oil pump can work normally before the next step;

3. Come on. Add heat transfer oil to the expansion tank oil tank, and through the circulation of heat transfer oil, input the heat transfer oil into various parts of the oil carrier, and then perform mechanical operations;

4. Observe the pipeline for gas leaks and leaks. At the same time, it is also necessary to determine whether the pressure of the model thermometer is normal during operation and the safety of the temperature and other environments.