Welcome to the website of Shanghai Endek Machinery Co., Ltd

hotline:+86-021-52822070

PRODUCT

PRODUCT Closed tower

Closed towerCharacteristics of adiabatic closed cooling tower products:

(1) Efficient cooling performance

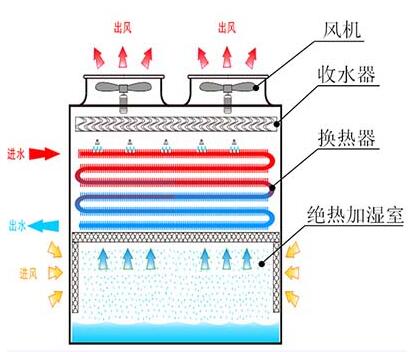

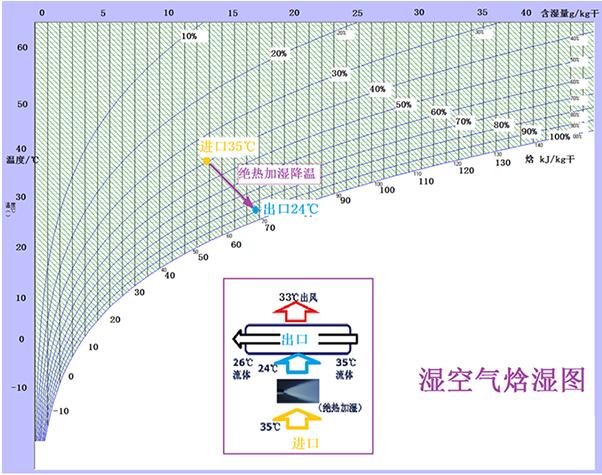

Unique adiabatic cooling design, the air undergoes adiabatic cooling, and the inlet temperature will be reduced to near the wet bulb temperature, greatly enhancing the cooling capacity; The unique design of copper tube aluminum fin heat exchanger has a heat transfer performance that is more than three times that of traditional copper tube, greatly improving cooling efficiency.

(2) Significant water-saving effect

The cooling method, mainly composed of saturated wet air cooling and supplemented by severe weather spray cooling and dry air cooling, replaces the traditional closed cooling tower with perennial spray cooling, saving over 50% of water throughout the year.

(3) Intelligent optimization operation control strategy

Track cooling loads and climate changes 24/7, adjust multi-mode operating conditions at any time, and ensure a savings of over 40% in comprehensive operating costs throughout the year.

(4) Professional and complete system support

A complete set of pumps, expansion tanks, water tanks, constant pressure water replenishment, exhaust, filtration, antifreeze, water treatment, pipelines, and control systems are provided to ensure that the system operates efficiently and without faults for more than 10 years.

(5) Remote monitoring and maintenance services

By applying internet communication technology, we can communicate with the after-sales service center of Kulun Service in real-time for each cooling system status of our customers, obtain professional maintenance guidance, and create more value for our customers.

(6) Flexible system expansion function

Modular design of adiabatic closed cooling towers, pump sets, and integrated PLC systems can flexibly expand the system.

2、 Adiabatic closed cooling tower:

(1) How to have efficient cooling capacity?

The specially designed copper tube aluminum fin heat exchanger has a heat transfer performance that increases by 2-3 times compared to ordinary copper tube bare tube heat exchangers;

Adopting adiabatic cooling technology to achieve adiabatic isoenthalpy cooling of air, increasing the heat exchange temperature difference of the heat exchanger, greatly enhancing the heat exchange capacity.

(2) How to save water and energy?

In summer, the ambient temperature is high and the heat dissipation is large. The adiabatic closed cooling control system automatically starts the spray cycle, which consumes a lot of water and energy, and has a short operating time;

During the transitional season, the wet bulb temperature in the environment is relatively low, and the control system automatically activates the adiabatic humidification cooling mode, eliminating the need to fully turn on the spray pump and fan, greatly reducing water and energy consumption.

(3) How to operate reliably and stably?

The adiabatic closed cooling tower operates in the adiabatic humidification mode for most of the year, greatly reducing the possibility of fouling in the heat exchanger, ensuring stable and reliable heat exchange performance throughout the year;

Customizing an overall cooling solution for customers, the adiabatic closed cooling tower, pump system, and pipeline layout have been optimized and designed, with good matching, high operating efficiency, and more complete control and protection logic to ensure the safe and stable operation of the adiabatic closed cooling system.

We have a professional customized development team that can customize bearing application solutions according to actual needs. We provide thoughtful services throughout the entire process, including plan designation, plan determination, order production, and on-site installation. If needed, please call+86-021-52822070,We will arrange professional personnel to contact you as soon as possible。