Welcome to the website of Shanghai Endek Machinery Co., Ltd

hotline:+86-021-52822070

PRODUCT

PRODUCT Mold cleaning

Mold cleaningThe NTC third-generation fully automatic multifunctional mold waterway cleaning machine is very suitable for cleaning the mold cooling waterway in various plastic or metal processing and forming industries such as automotive parts, household appliances, electronic products, and packaging.

Machine features:

1. Innovative reciprocating+pulse cleaning method, efficient and fast completion of waterway cleaning operations.

2. One click fully automatic cleaning operation, touch screen human-machine interface dialog box, easy to operate and maintain.

3. The ultrasonic flow detection method accurately monitors and compares the changes in mold water flow, making it convenient to inspect the cleaning effect.

4. Numbered mold waterway cleaning, flow detection, data recording and output are conducive to scientific implementation of waterway maintenance.

5. Designed with casters, it is easy to move and can flexibly correspond to offline and online mold waterway cleaning.

6. Strong punching and blocking mode, with powerful and precise impact on stubborn mold waterway blockage points, efficiently unblocking the mold waterway.

Technical principles:

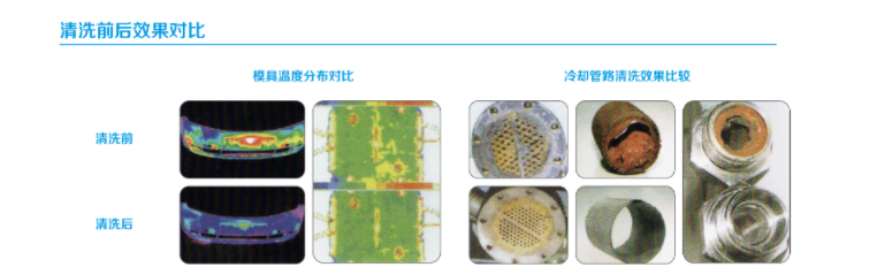

The NTC mold waterway cleaning machine adopts high-speed high-pressure water air mixing technology, which automatically controls multiple frequency air pressure pulses, causing frequent gas erosion when the cleaning liquid enters the waterway at high speed. At the same time, using forward and reverse cleaning technology, the water flows back and forth, generating alternating pressure. Under this action, bubbles in the pipeline explode, causing damage to the pipe wall surface

The surface forms a huge impact effect, stripping away scale and rust from the pipe wall, and the impact carries out various attachments and chest corrosion in the water path, completing pipeline cleaning.

The functional introduction includes:

1. Intelligent control; 2. Reciprocating cleaning; 3. Intelligent turbocharging; 4. Strong flushing and blocking; 5. Pulse cleaning; 6. Front and rear emergency stops; 7. Mold cleaning and drainage; 8. Multi channel flow monitoring; 9. Cleaning of numbered molds; 10. 1000 group number records; 11. Export cleaning records; 12. Pipeline leakage and pressure testing; 13. Protection against pipeline leakage; 14. Environmental protection discharge of sewage; 15. Automatic heating of water tank; 16. Automatic replenishment of water tank; 17. Multiple language systems; 18. SUS304 structure; 19. Automatic collection of washing solution; 20. Padlock emergency stop switch.

We have a professional customized development team that can customize bearing application solutions according to actual needs. We provide thoughtful services throughout the entire process, including plan designation, plan determination, order production, and on-site installation. If needed, please call+86-021-52822070,We will arrange professional personnel to contact you as soon as possible。